Vicon RV 5216 - 5220 Plus

Högkapacitspressar med flexkammare, PowerBind näbindning och Intelligent Density 3D.

Baldiameter från 0.60m upp till 1.65 och 2.00m.

Beskrivning

Flexpressar med hög kapacitet

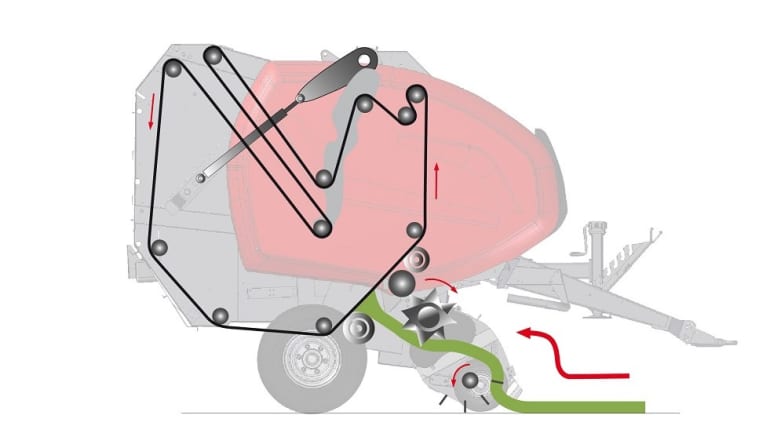

Senaste Vicon RV 5200 Plus-serien kombinerar lönsam hög prestanda med marknadsledande baldensitet. De nya modellerna i Plus-serien drar nytta av en mängd uppgraderingar som är utformade för att öka produktionen och minska underhållskraven. Pickupen har uppdaterats med längre pinnar och bredare svep för bättre rengöring. Pick-up- och huvudbalkkammardrivningar är utrustade med en ny HBC-kedja med hög specifikation. Valsgrödpressen har ökat lyft för bättre matningskapacitet och innehåller fasta axlar med invändiga lager. RV Plus-serien är ledande inom baldensitet, uppnådd genom Intelligent Density 3D, vilket gör att du kan välja den baldensitet som passar bäst för dina grödor.

Fördelarna:

- Bred 2.2m lågprofils-pickup & högpacitets inmatningssystem.

- SuperCut 14- och 25-knivarssystem för noggrann försnittning och bästa foderkvalité.

- Parallelograms DropFloor för enkel avblockering.

- Tre olika densiteter, förvalda direkt frå traktorhytten.

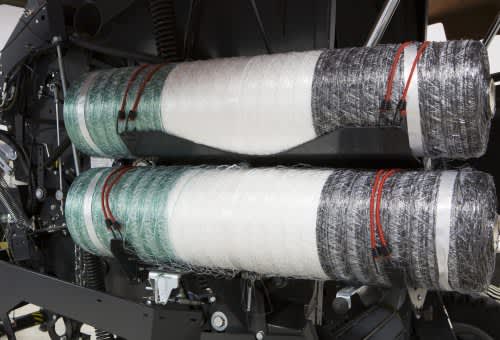

- PowerBind med direkt nätinjektion för snabb och pålitlig bindning.

- Enkel lastning av nätrulle.

- Isobus-kontroll.

Egenskaper

- 2.0 or 2.2m pick-up with small diameter pick-up reel for fast and efficient throughput.

- Pick-up with 4 or 5 rows of tines respectively.

- Twin cam tracks on the 2.2m wide pick-up.

- Tine bars with two central supports on the 2.2m wide pick-up.

- Small diameter pick-up design.

- Roller crop press is standard on the 2.2m wide pick-up.

- Narrow transport width.

SuperCut-25

- The SuperCut-25 pre-chopping system offers the ultimate solution for short chop baling with a chop length of 40mm. The short and precise chop provides dense and airtight bales for the best possible silage quality.

- The operator can choose to engage 25, 13, 12, 6 or 0 knives, giving maximum flexibility of operation.

- The SuperCut- 25 knives are fitted with dual action protection against foreign objects. Each knife is individually spring protected and can move in two directions

SuperCut-14

- The SuperCut-14 knife chopping system provides a fast and efficient flow into the baler. With a chopping length of 70 mm it is the ideal solution for producing tight bales with superb silage quality.

- Each individual knife is spring protected against foreign obstacles. The knife will immediately return to its working position once the obstacle has passed.

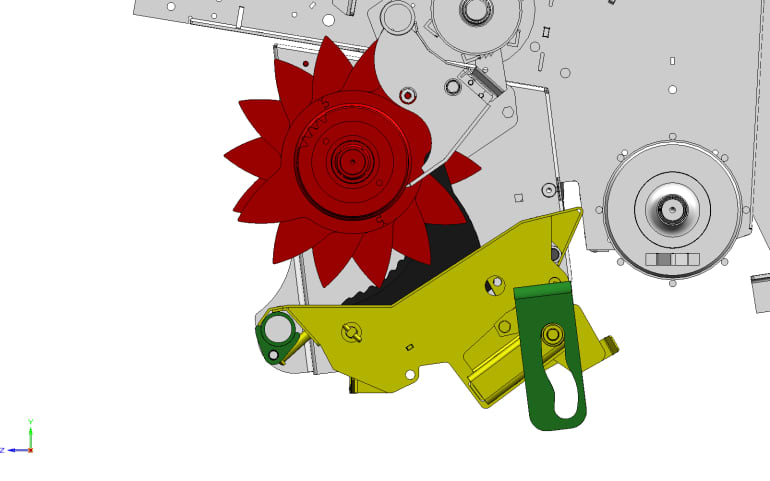

PowerFeed Rotor Intake

- Truly impressive intake capacity can be achieved with the PowerFeed rotor intake system - handling all crop types with ease, whatever the conditions.

- The PowerFeed rotor with its 13 rotor fingers proactively forces the material into the bale chamber for higher intake speed and capacity proving instant bale start.

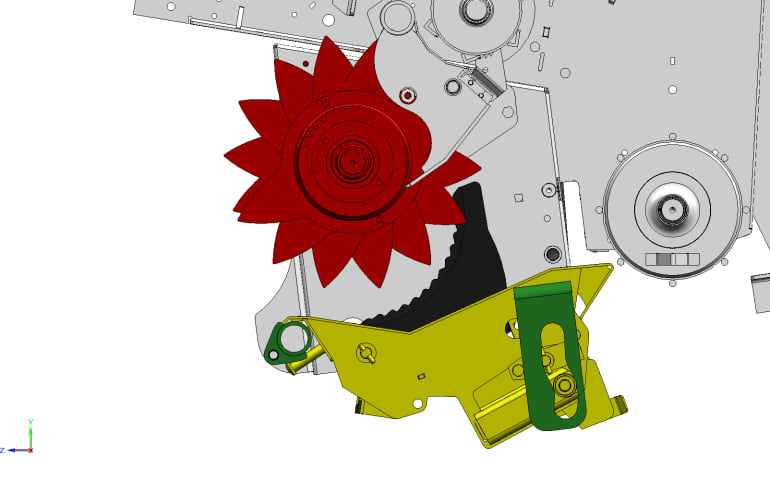

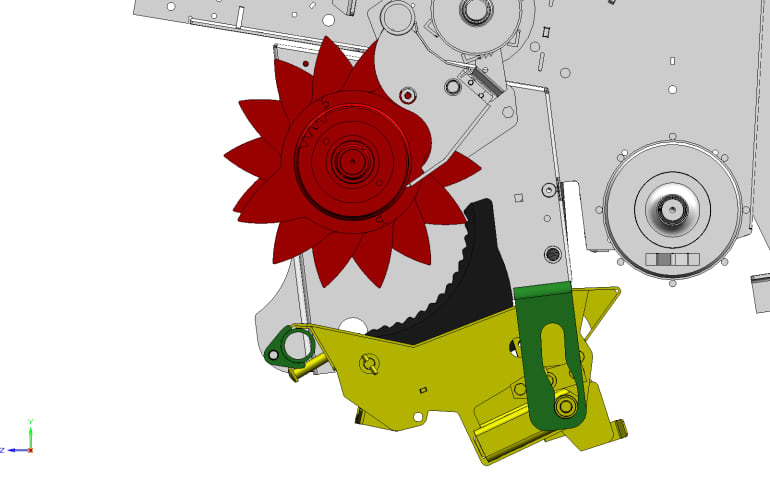

Parallelogram DropFloor System for faster Unblocking

Parallelogram Drop Floor enables the operator to clear blockages easily from the tractor cab without any crop loss.

Drop the floor to free the rotor of blockage, engage the PTO to feed the blockage through and close the floor to continue baling.

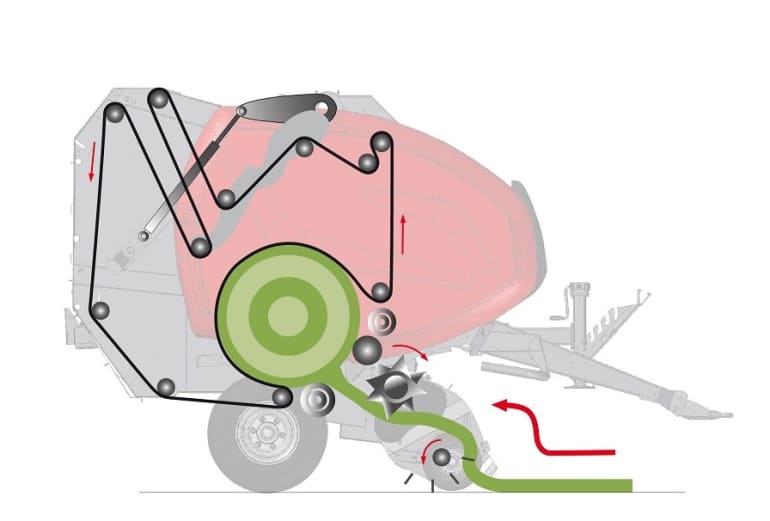

- Setting and selection of correct bale density is vital in order to get the right quality of the bale. Especially when the baler is utilized through the full season in different crops like straw, hay and silage it is important to adjust the bale density to the specific type of material.

- Intelligent Density 3D with 3 pre-selected bale density settings making it very easy to choose the correct bale density in different crops.

- It is however still possible to customize the bale density in 3 separate zones each with a choice of diameter and pressure to match specific requests.

- With the new Intelligent Density 3D application, three pre-configured bale densities are available from the menu of the control box, each of them tailored for straw, hay or silage. This makes the change-over from different crop materials much easier limiting the risk of mistakes.

- Baling dry straw and want the heaviest bales possible? Maximum pressure is set in every zone.

- Baling hay? The soft centre core is set to let the bale breath, with gradually increasing pressure towards the outer layer.

- Baling wet silage? Pressure is reduced in the centre and mid zones.

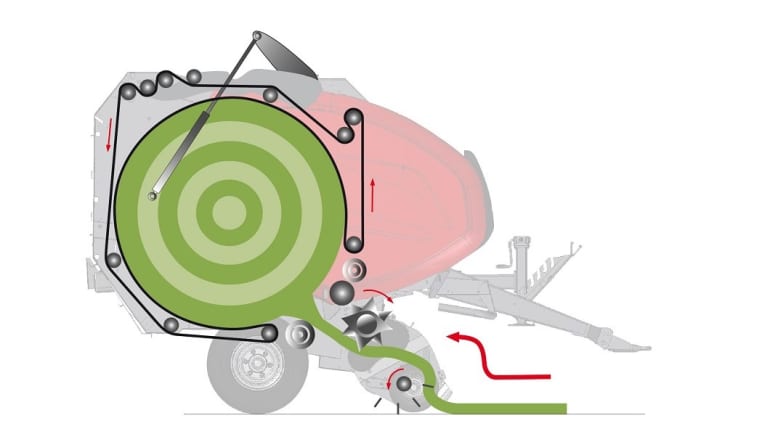

- One of the fastest net wrap actions available. This means minimum downtime and maximum time baling.

- The net is fed directly into the bale chamber by an injection arm in a flat movement angle to keep the net tight at all times.

- Accurate and extremely reliable net injection.

- No interference from external factors such as wind and crop.

- When the bale is 90% complete the injection arm moves forward, ready for the net injection. No time is spent picking up the net.

- Very low loading height, for maximum convenience and time saving. To replace the empty roll just swing out the shaft and replace it with a new roll

- The PowerBind net wrap system allows the net to extend past the edge of the bale.

Techno-Pack has been developed to offer professional farmers and contractors the optimum solution in terms of crop harvesting management. The moisture level of crop entering the bale chamber during the baling process is continuously measured and displayed on the baler terminal. Sensor plates are mounted in the lower part of the bale chamber, from which the system calculates the percentage of moisture inside the bale. The system is able to detect moisture levels up to 50% allowing the driver to decide at any time if crops such as hay or straw are fit to bale - your assurance of always preserving the best possible forage quality.

ISOBUS Control

IsoMatch Tellus

- The IsoMatch Tellus is the new virtual terminal, offering 2 Interface screens in 1 terminal. The large 12” easily programmable touch screen offers ergonomic use and is designed for long days of operation.

- Due to the increasing number of functionalities that can be added to a machine such as cameras, the operator can use the baler interface in the top screen and a camera display in the bottom screen, to monitor finished bales.

- Another possibility is to use the baler interface in the top screen and the tractor interface screen at the bottom.

IsoMatch Tellus GO+

- IsoMatch Tellus Go is a full Isobus terminal able to control all Isobus machines in a very simple way.

- Compact design makes it easy to integrate in the tractor cab despite the comfortable 7" touch screen allowing perfect machine set-up and control. With hard keys combined with the rotary switch on right hand side, for direct access to main functions while driving.

TIM (Tractor Implement Management)

TIM is a cross-product and cross-manufacturer ISOBUS solution for the agricultural machinery industry whereby the implement is able to control certain tractor functions. It enables two-way communication between tractors and implements, allowing both machines to work in perfect harmony. As well as increasing efficiency, the possibility of human error due to fatigue is also greatly reduced. TIM technology has the advantage of significantly increasing driver comfort by automatically performing many of the repetitive actions of the baling process.

The cost aspect is another factor to bear in mind. Highly efficient use of TIM-equipped baler results in lower costs for parts that wear out.

- TIM system as optional equipment

- TIM takes most of the work off the operator's hands when baling

- Significant increase in comfort for the operator, as endless work steps are saved

- Reduced operator fatigue and faster completion of work while maintaining high bale quality

- High user-friendliness of the TIM system, which even regularly changing operators can quickly master

Focus 3 Control

Kverneland Group Mechatronics has recently launched a new operator terminal, the Focus 3. This terminal is developed for specific implement types and will only be delivered as package for those implements, together with the electronics for balers. The terminal Focus 3 is positioned in the market as an economy solution.

- Focus 3 terminal is easy to learn and very intuitive, with focus on functionality and operating simplicity.

- Focus 3 terminal is a universal control terminal which can also be used with other implements from Kverneland Group.

- Focus 3 terminal gives you full control of all functions from the tractor cab. They are shown on a large and very clear digital display.

- Focus 3 terminal monitors and controls all necessary functions with all relevant parameters / information visible at a glance. The control box is also driving the binding automatically without any intervention from the operator.

Precisionsjordbruk

When deciding what equipment to purchase, it is not always easy to find the optimal solution in the broad market offering of today. Technology is developing fast and tractors and implements are more and more equipped with high tech electronics. We understand this complexity and are committed to provide you with easy farming solutions. Therefore these cost-efficient ISOBUS Universal Terminals, IsoMatch Tellus and IsoMatch Tellus GO+ are made for easy machine control and efficient farming.

With its advanced hardware and software features, the IsoMatch Tellus PRO provides the optimal precision farming solution for an all-in-one control system inside your tractor cab.

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything you need to get the maximum out of your machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives you the opportunity to view and control two machines and processes simultaneously.

Work easy. Be in control.

The new IsoMatch Tellus GO+ offers a more powerful processor, allowing for significantly faster responsiveness and increasing the ease of navigation. The IsoMatch Tellus GO+ can handle demanding applications like IsoMatch FarmCentre, allowing advanced features and remote connection to your implement for a higher yield at less cost.

Ease of setting up the machine with the soft keys and simple use of the hard keys and rotary switch for optimal control while driving remains the trademark of the IsoMatch Tellus GO+ terminal, and is testimony to Vicon's commitment to bring farmers the most advanced technologies to improve productivity and efficiency.

Teknisk specifikation

Teknisk specifikation

Ladda ner broschyrenBaldiameter |

Inmatninggystem |

Binding |

|

RV 5216 Plus SC-25 |

1.20 x 0.6 - 1.65m |

SuperCut-25 |

Nät |

RV 5220 Plus SC-25 |

1.20 x 0.6 - 2.00m |

SuperCut-25 |

Nät |

IsoMatch Tellus GO+

IsoMatch Tellus GO+